Additional Information

There are various applications for woven geotextile, but it is mostly used in the field of soil erosion control, soil stability and drainage.

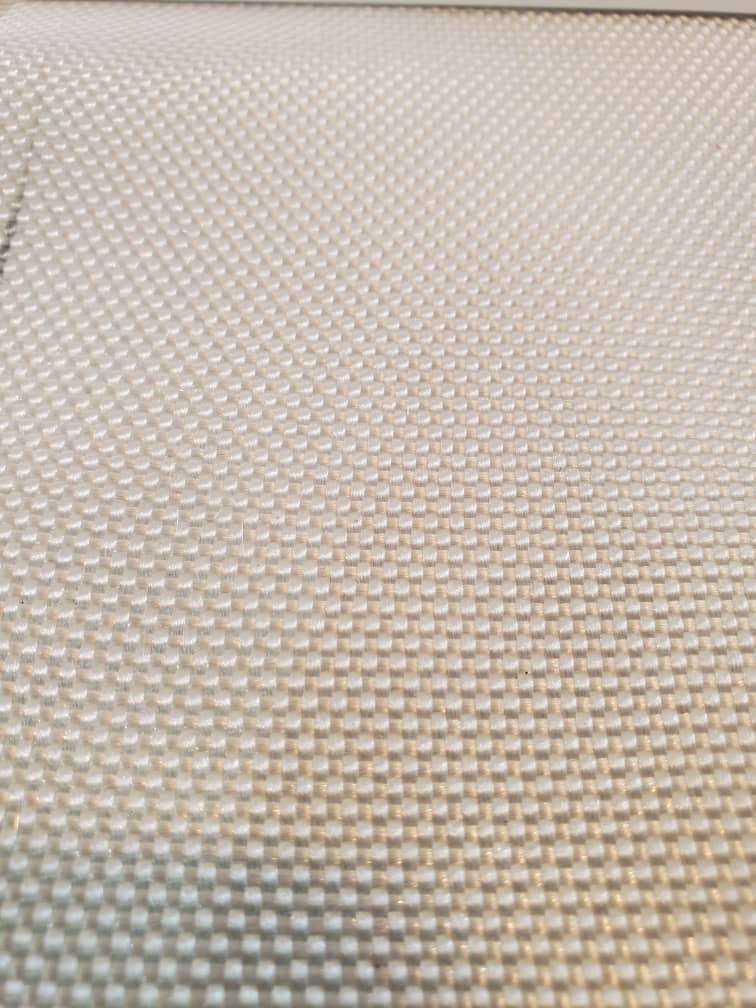

In the manufacture of woven geotextile fabric, a method similar to the manufacture of other industrial fabrics is used to make a strong woven fabric. The fabrics used in the manufacture of woven geotextile are very lightweight and strong, so moisture will not pass through them quickly or effectively. Woven geotextile fabrics also have tensile strength and have a plastic appearance so that you can see the pattern of the weave on their surface.

As you know, woven geotextiles are produced using weaving. In this process, the warp and weft yarns woven vertically and horizontally give woven geotextiles a high load capacity, which makes woven geotextiles very suitable for applications such as airport runway construction.

Woven Geotextile Weave

The weaving of yarns in woven geotextile has two meanings, which means that these geotextiles are not very porous, which makes them not very suitable for civil engineering projects where drainage is very important. But this feature makes them ideal for some civil engineering erosion control projects where water must be transferred from the surface without being drawn down through the soil below. Woven geotextile is an affordable solution for a variety of applications, including:

- Stabilizing construction entrances and staging areas.

- Bridging soft soils.

- Separating different soils.

- Reinforced soil structure.

- Coastal erosion control.

Woven geotextiles are today one of the most widely used types of geotextiles, which are used in various industries such as road construction, railways, construction of defensive barriers in banks and construction of runways in airports.

Features of Woven Geotextile

- Woven geotextile is very lightweight, so it is easier to transport and move on site.

- The costs of transportation and labor are much lower, so they are very affordable.

- Woven geotextile has high tear strength.

- Woven geotextiles also have high electrical resistance.

Technical Specifications

|

Mass per unit |

g/m2 |

400 |

200 |

ASTM D5261 |

|

Tensile Strength(MD) |

KN/m |

100 |

51 |

ASTM D4595 |

|

Elongation(MD) |

% |

10 |

14 |

ASTM D4595 |

|

Tensile Strength(CD) |

KN/m |

102 |

50 |

ASTM D4595 |

|

Mass per unit |

g/m2 |

400 |

200 |

ASTM D5261 |

|

Elongation(CD) |

% |

11 |

13 |

ASTM D4595 |

|

Grab Tensile(MD) |

N |

4850 |

3650 |

ASTM D4632 |

|

Elongation Grab(MD) |

% |

12 |

15 |

ASTM D4632 |

|

Grab Tensile(CD) |

N |

4600 |

3350 |

ASTM D4632 |

|

Elongation Grab(CD) |

% |

13 |

17 |

ASTM D4632 |

|

Trapezoid (MD) |

N |

1780 |

1260 |

ASTM D4533 |

|

Trapezoid (CD) |

N |

1670 |

1170 |

ASTM D4533 |

|

Effective Opening Size(O90) |

mm |

0.06 |

0.09 |

|

Installation and implementation steps

To install geotextiles properly, engineering instructions should be considered:

- The desired surface should be cleaned of weeds, extra soil, sharp and sharp stones, etc.

- All cracks and seams and soil highs and lows should be taken and corrected.

- The woven geotextile fabric should be spread out with minimal wrinkles and the seams should be taken with pins, nails, industrial welding machines, etc

- The use of adhesive coating between 1-1.351/M2 of remaining asphalt should be done evenly.

- In the end, a hot coating or asphalt should be poured over them.

Applications

Road construction, dam construction, wharf, oil and gas pipelines, road paving and soil reinforcement.

Woven geotextile due to the materials used in its construction, which is based on polyester and polypropylene and a combination of other polymer materials with grammage, which is formed by placing fine polymer fibers together and interweaving.

Woven geotextile has many applications. Applications of woven geotextile can be used in a wide range of construction industry and civil engineering due to its resistant texture. From retrofitting and protection, bank security to road construction and street drainage. In general, woven geotextile has a plastic-like texture and can show very high tensile strength, that’s why it is the best option for use in heavy construction projects that require soil reinforcement.

One of the unique features of woven geotextile is that it strengthens weak soil and prevents its erosion, and enables construction in places that lack proper infrastructure. Also, the woven geotextile prevents the separation of soil layers and prevents the occurrence of erosion in the soil or preventing the sinking of oil and liquid waste into the soil by using the woven geotextile.

Also, in areas where there is good soil for airport runway design, the use of woven geotextile can be considered as a reliable solution for strengthening the runway. Woven geotextile is also a suitable option for use in nature-friendly projects and can prevent damage to nature.

Related products

Geosynthetics

Geosynthetics

RAINFORCED TEXTILE

Geosynthetics

العربية

العربية فارسی

فارسی

Reviews

There are no reviews yet.