Further Details

Advantages of Fabric Formed TEXLYPS

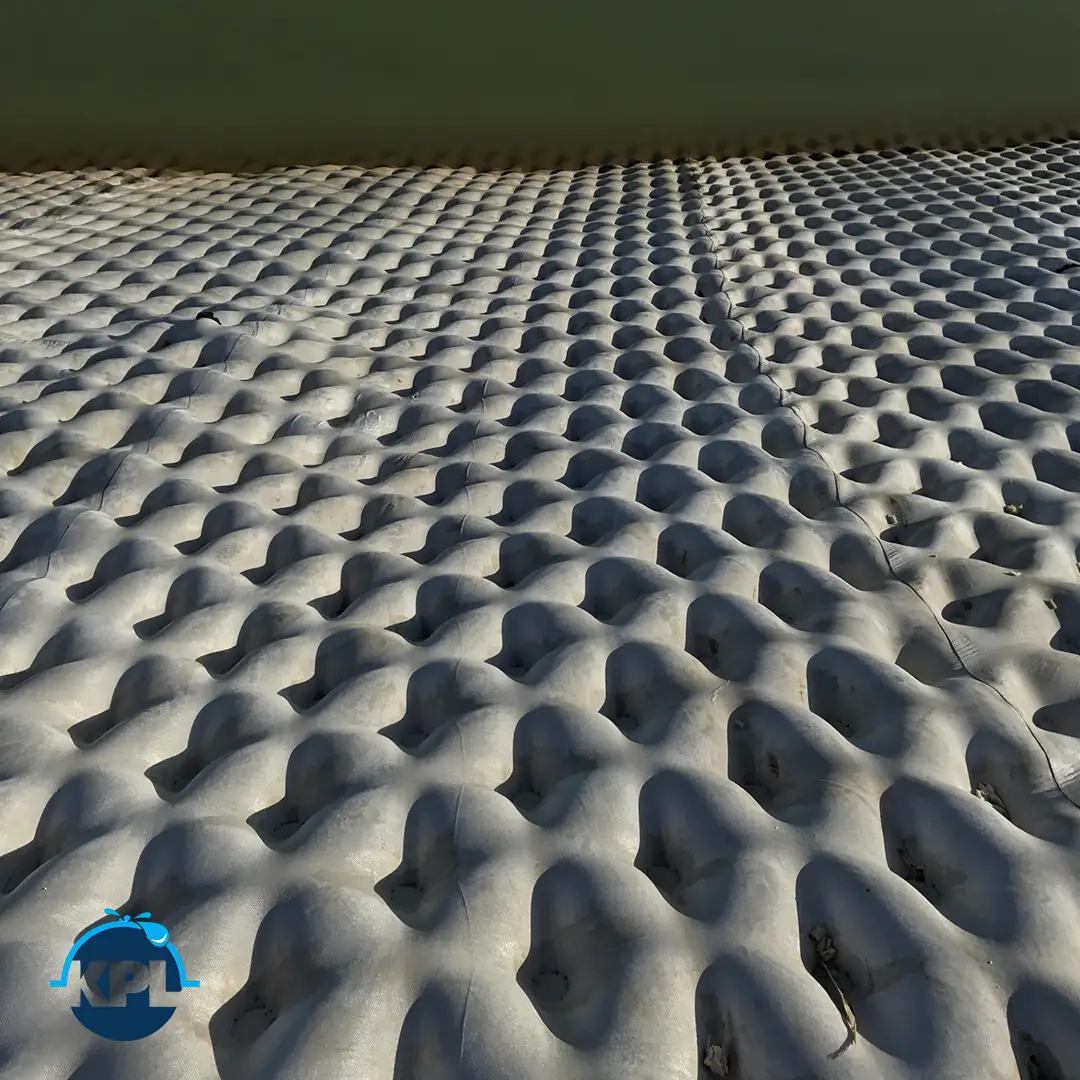

This Fabric Formed TEXLYPS system does not need molding and reinforcement because the chambers of the Fabric Formed TEXLYPS play the role of a mold for concrete and the threads that connect the two lower and upper layers of the Fabric Formed TEXLYPS increase the tensile strength of concrete. In this way, the costs of preparing the mold and reinforcement are eliminated and the execution speed increases significantly.

Flexibility

The flexibility of Fabric Formed TEXLYPS creates a layer resistant to asymmetric settlements during the operation period, while other products will crack due to asymmetric settlements.

Tensile strength

The high tensile strength of the woven geotextile materials forming the Fabric Formed TEXLYPS creates a permanent system without the need for periodic maintenance. Also, the tensile strength of Geotextile prevents the system from cracking during concrete shrinkage, while the occurrence of shrinkage cracks in concrete linings is almost inevitable.

It provides the possibility of mooring a boat or marine machinery next to the cover. Due to the possibility of changing the dimensions of the rolls, it can be used in the construction of ponds and canals with many twists and turns or recreational complexes with special use. This Fabric Formed TEXLYPS system has the ability to be installed under water and at high river flow speed. Meanwhile, other geotextile and armor products or systems do not have such an advantage.

One of the most important advantages of this Fabric Formed TEXLYPS system is resistance to corrosion and erosion. The lack of chemical reaction of geotextile with environmental elements and fluids that are in contact with it causes the concrete inside the Fabric Formed TEXLYPS to remain immune and the life of the system increases significantly. This is while other similar products suffer from corrosion and erosion due to the direct contact of concrete with environmental factors.

Technical Specifications

|

Thickness |

mm |

0.65 |

ASTM D5261 |

|

Tensile Strength(MD) |

KN/m |

70 |

ASTM D4595 |

|

Elongation(MD) |

% |

15 |

ASTM D4595 |

|

Tensile Strength(CD) |

KN/m |

68 |

ASTM D4595 |

|

Elongation(CD) |

% |

15 |

ASTM D4595 |

|

Grab Tensile(MD) |

N |

3440 |

ASTM D4632 |

|

Elongation Grab(MD) |

% |

14 |

ASTM D4632 |

|

Grab Tensile(CD) |

N |

2240 |

ASTM D4632 |

|

Elongation Grab(CD) |

% |

15 |

ASTM D4632 |

|

Trapezoid (MD) |

N |

1020 |

ASTM D4533 |

|

Trapezoid (MD) |

N |

980 |

ASTM D4533 |

Installation and implementation steps

The installation of Fabric Formed TEXLYPS can also be done underwater, and compared to traditional methods such as porcelain stoneware, riprap, or concreting, in terms of economy, time and durability, it is much more economical and justifiable.

Implementation method Fabric Formed TEXLYPS

Fabric Formed TEXLYPS is easily portable with workers or light transport equipment. First, the installation bed is leveled and usually a non-woven geotextile layer is placed on it. Fabric Formed TEXLYPS panels are connected to each other at the installation site and form an integrated system.

The location of the concrete pumping opening is either installed at the beginning or it is cut into the site with a mark made in the factory and ready for pumping. Concrete with special specifications is pumped into the Fabric Formed TEXLYPS. The execution speed of the Fabric Formed TEXLYPS depends on the equipment of the concreting workshop and the readiness of the substrate. In case of personnel coordination, up to 300 square meters per day can be covered with this method.

Considering that Fabric Formed TEXLYPS can be used on slopes of 35 to 45 degrees with soil density of 90 to 95%. If the slope is estimated to exceed this value, it is suggested to use reinforced soil system to stabilize the slope.

Applications of Fabric Formed TEXLYPS

Coasts, rivers, canals, rivers, lakes, water reservoirs, anchorage, harbors and docks, protection of oil and gas pipelines, bridge columns exposed to water flow.

- Cushion for erosion control of levees and steep slopes

- Cushion for water reservoirs

- Maintenance of pile heads and control of bridge erosion

- Making packages consisting of woven geotextiles for underwater concrete projects

- Specific designs for protection and control of the immersion force of underwater pipelines

- Providing waterproofing and erosion control designs for underwater concrete walls

- Hydraulic erosion control of channel walls, gutters, rivers and coasts

- River and river margins that allow planting of plants for environmental protection

You can always get guidance from the engineers of KPL Co., for purchase or consultation at any stage of the project to select the best product.

Related products

Fabric Formed

Geosynthetics

Geosynthetics

Geosynthetics

العربية

العربية فارسی

فارسی

Reviews

There are no reviews yet.